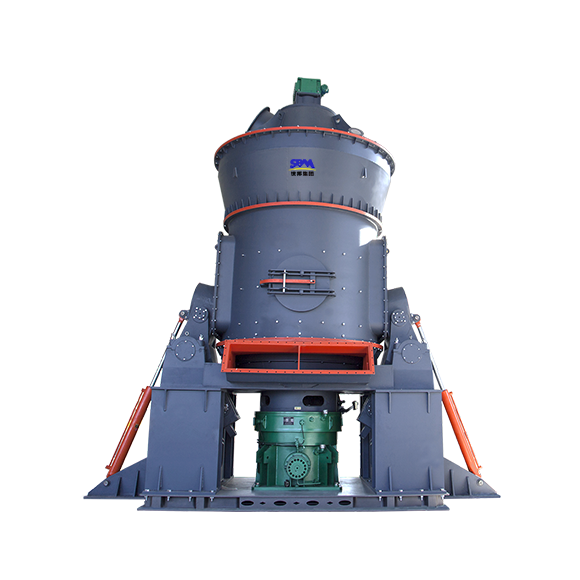

According to accumulation and experimental analyses of on-site test data for more than thirty years, SBM, a Chinese grinding mill manufacturer, has researched and developed the fifth-generation pendulous hanging grinding mill – MRN grinding mill. All non-combustible and non-explosive brittle mineral products whose Moh’s hardness are below Grade 7 and water content below 6% could be ground by this grinding mill.

MRN Pendulum Roller Grinding Mill Working Principle

After hammer crushers (or jaw crushers) break large bulky materials to smaller ones, elevator works to send materials to material hopper. Then, by electromagnetic vibrating feeder, broken materials are evenly and quantitatively sent to the grinding chamber of MRN Pendulum Roller Grinding Mill. After grinding, materials are blown away by airflow to the powder concentrator for classifying. Under the action of the impeller of powder selector, materials which fail to meet fineness would be sent back to grinding chamber to get another grinding while qualified powders would be collected by cyclone powder collector and discharged from the bottom as finished products. And, after that, the airflow would go into the fan along with the air return duct at the top of cyclone power collector. This system adopts a closed circuit and runs under positive and negative pressure.