Sustainable Grinding Mill Operation Practices As industries increasingly focus on sustainability, optimizing the environmental impact of production processes becomes essential. The European Trapeziu……

Engineer one-to-one for you, draw up plans in time, and provide investment estimates in time!

Online ChatGet PriceAs industries increasingly focus on sustainability, optimizing the environmental impact of production processes becomes essential. The European Trapezium Grinding Mill, known for its efficiency and performance, also offers opportunities for adopting sustainable operation practices. Here’s how you can implement sustainable practices in the operation of your grinding mill:

Reducing energy consumption is a key aspect of sustainable operation. The European Trapezium Grinding Mill is designed for high energy efficiency. To further minimize energy use, regularly review and adjust operational parameters such as grinding pressure, speed, and airflow. Implement energy-saving practices like utilizing variable frequency drives (VFDs) to control motor speed and reduce power consumption during low-load conditions.

Efficient grinding processes help minimize waste. Ensure that the European Trapezium Grinding Mill is properly calibrated to reduce the amount of material that needs to be reprocessed. Implement measures to recycle or repurpose by-products and reduce overall waste. This approach not only conserves resources but also minimizes the environmental footprint of your operation.

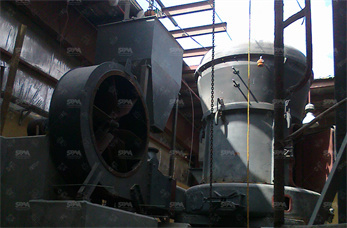

Regular maintenance and proper operation are crucial for sustaining equipment efficiency. The European Trapezium Grinding Mill’s robust design ensures long-term performance. Conduct routine inspections, clean air and dust filters, and replace worn parts as needed. Maintaining optimal equipment performance prevents excessive energy consumption and prolongs the life of the mill.

Effective dust control is vital for both environmental and health reasons. The European Trapezium Grinding Mill is equipped with advanced dust collection systems to capture and manage airborne particles. Ensure that dust control systems are regularly checked and maintained to prevent dust emissions and maintain a clean working environment.

Efficient use of materials contributes to sustainability. Use precise grinding parameters to ensure that raw materials are processed effectively with minimal loss. By optimizing the material feed rate and processing conditions, you can achieve the desired product quality while minimizing material wastage.

Where possible, integrate renewable energy sources such as solar or wind power into your grinding mill operation. Using renewable energy reduces reliance on fossil fuels and lowers greenhouse gas emissions. Explore options for installing renewable energy systems to power your grinding mill and contribute to a more sustainable energy mix.

Education and training are crucial for implementing sustainable practices. Ensure that all personnel are trained in energy-efficient operation, waste reduction techniques, and proper maintenance procedures. An informed and engaged team can help identify opportunities for improvement and ensure that sustainable practices are consistently applied.

Regularly monitor and evaluate the performance of your grinding mill to identify areas for improvement. Use performance data to assess the effectiveness of sustainability measures and make adjustments as needed. Implementing a continuous improvement approach helps maintain and enhance the sustainability of your operations over time.

In conclusion, adopting sustainable grinding mill operation practices is essential for reducing environmental impact and enhancing overall efficiency. By optimizing energy consumption, reducing waste, maintaining equipment performance, implementing dust control measures, optimizing material usage, utilizing renewable energy sources, training staff, and monitoring performance, you can ensure that your European Trapezium Grinding Mill operates in an environmentally responsible manner. These practices not only contribute to sustainability but also improve operational efficiency and reduce costs.

Powder Grinding Mill for Sale: Exploring the Benefits of Raymond Mill In the realm of industrial grinding equipment, the Raymond mill stands out as a versatile and reliable option for powder process……

Complete Stone Powder Milling Plant: European Trapezium Grinding Mill In the realm of industrial minerals, the demand for high-quality stone powders is ever-increasing. From construction materials t……

Innovative Mineral Processing Plant Machinery The European Trapezium Grinding Mill is at the forefront of innovative mineral processing plant machinery, offering unparalleled efficiency and precisio……

Modular Grinding Mill Production Line Designs In modern industrial operations, the design and flexibility of grinding mill production lines are crucial for achieving efficiency and scalability. The ……